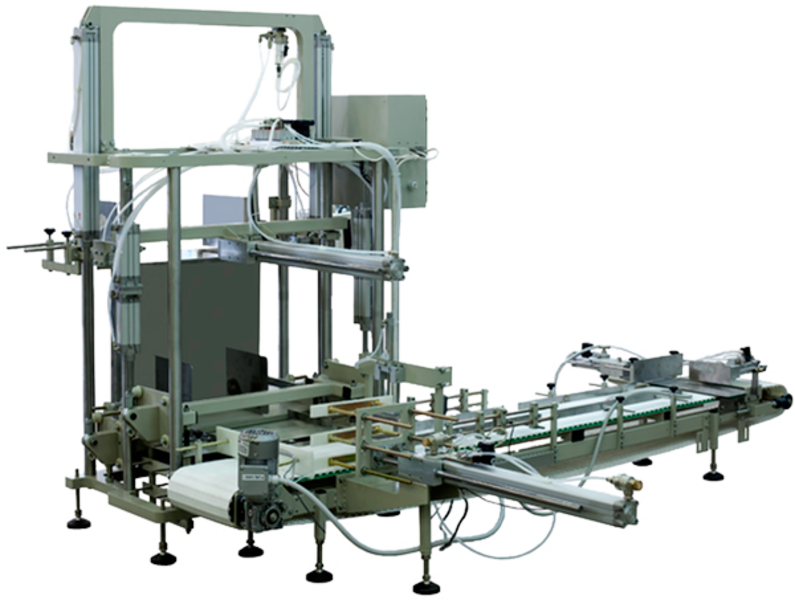

Automatic group packaging machine AGU 60

Automatic group packaging machine AGU 60 is designed for collecting products for their subsequent shrink wrapping.

Automatic group packaging machine consists of preliminary product grouping conveyor, displaceable grouping unit, storage unit, vertical lift conveyor and control panel.

For the purpose of subsequent shrink wrapping, AGU 60 is completed with UMP 600 PT machine, built by Thermo-pack, Ukraine.

Products grouping AGU 60 is to be completed with delivery table and roller conveyor.

Packaging in cardboard boxes is to be done in semi-automatic mode.

Packages from brick bag forming machine are moved to the preliminary product grouping conveyor where they are to be grouped in lines, 3-5 items each. This product group is to be moved further to the storage unit which is moved one step up. Grouping unit repeats this operation 2-4 times. Then grouping unit moves all lines of product to the vertical lift conveyor and the cycle is to be started again.

Vertical lift conveyor moves all bundle of packages up for further packaging in cardboard boxes or shrink wrapping.