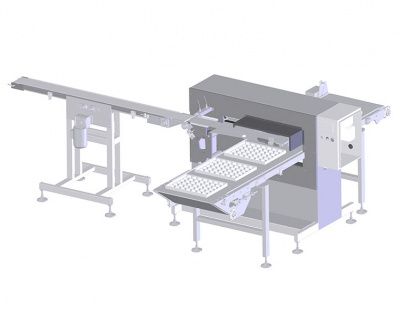

Plastic cup denester UBT-40

Purpose and equipment

Accurate plastic cup denester is designed to automatically pick the cup out of the magazine and place it on a conveyor belt for further filling with the product. Versatile automation solution for cup handling which is easy to be integrated in any upgraded food technological line.

Delivery

information

Delivery options: ✔ Customer pick-up ✔ Road transport ✔ Rail transport ✔ Air transport ✔ Sea transport

Warranty

information

✔ Warranty and post-warranty services ✔ Prompt maintenance services ✔

Consultations on equipment options, equipment diagnostics, equipment

troubleshooting, settings ✔ Commissioning and start-up ✔Customer

personnel training ✔ Equipment trial testing ✔ Spare parts, wear parts

and components delivery

Specifications

Power supply

1 phase, 220 V, 50 Hz

Installed power, kW

0,25

Dimensions (LxWxH), no more, mm

970x950х1930

Weight, kg (max)

150

Types of products

UBT-40 is equipped with state-of the art control system:

-

Plastic cup availability

-

Cylinder positions

-

Vacuum suction level

- If an unforeseen situation arises, malperformance or no tare, the denester stops its operation and goes into the standby mode up to up to the follow up remedial actions

- Built-in sensors Festo, Sick и Schneider Electric together with Siemens controller allows guiding the operation of the device at the highest level

- Stainless steel design UBT-40 at request

Recommended:

If you have any questions - contact us!

Our YouTube channel

Our YouTube channel