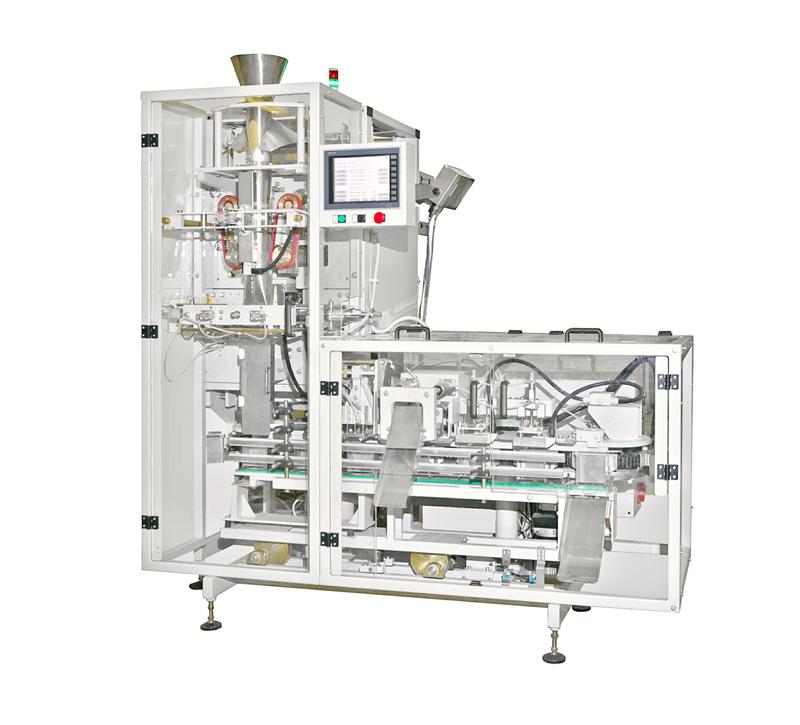

Brick bag forming machine AFB60-2S

-

Automatic machine AFB60-2S consists of a shake-proof steel frame and a magazine for kraft bag loading, a bag opening (height adjustable for product settling) and top folding units, cutting, folding and gluing the package top with hot glue, all installed on a frame.

-

Control of all operating parameters of the machine and synchronization of drive movements is performed by a programmable logic controller. A single (for a weigher and packaging machine) 7” graphic display is used to enter and display the parameters. The diagnostics of units and collecting statistical data are continuously performed during operation.

-

Automatic machine AFB60-2S is integrated with an auger filler SH2S

Our YouTube channel

Our YouTube channel