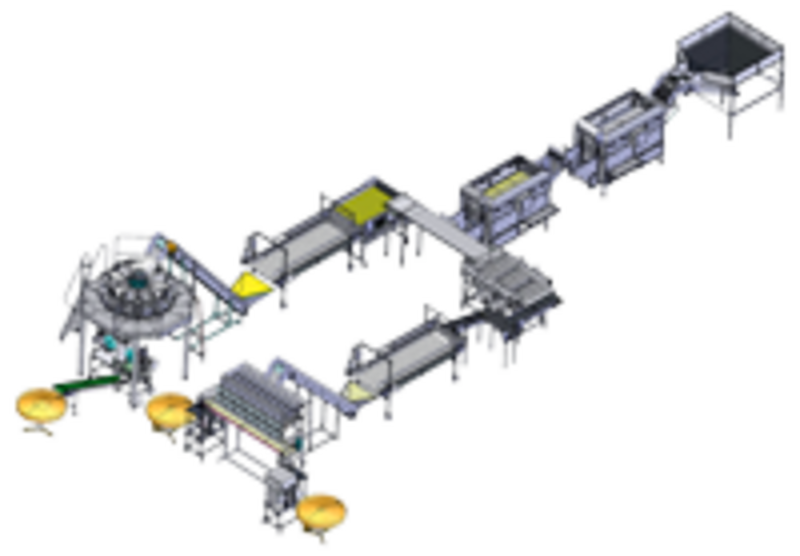

Cherry tomato weighing and packaging line

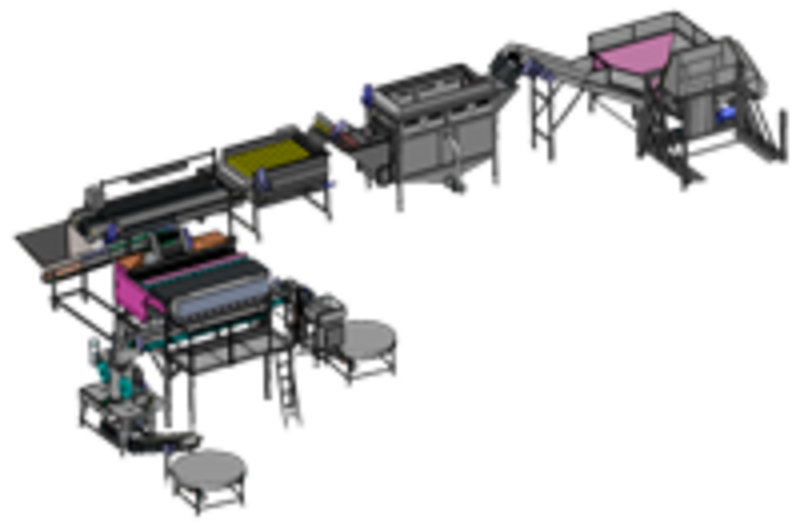

The line is designed for cherry tomato inspection, accurate dosing in tray with lids, lid closing, label application on the top and bottom of the tray. Product label on the top and termo label with graphic and text information. Then the trays are accumulated by the roller conveyor.

Effective average performance: 30-40 pack/min (depends on a dose weight).

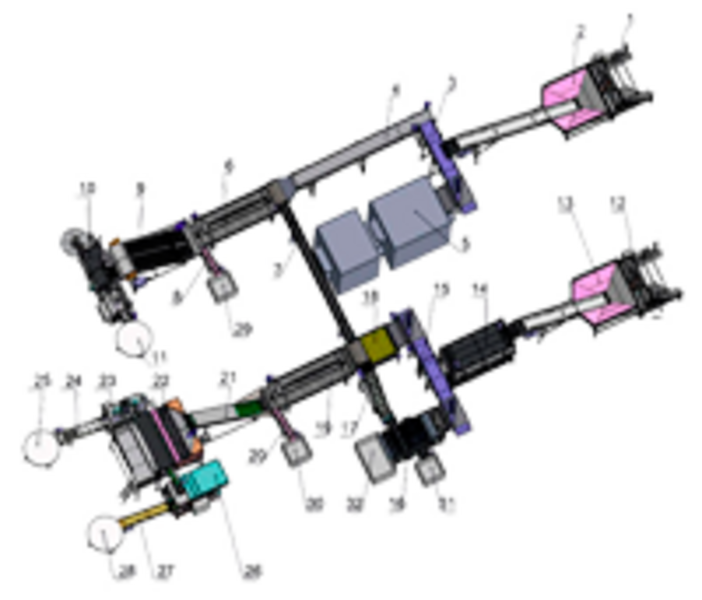

Complete set of the equipment:

-

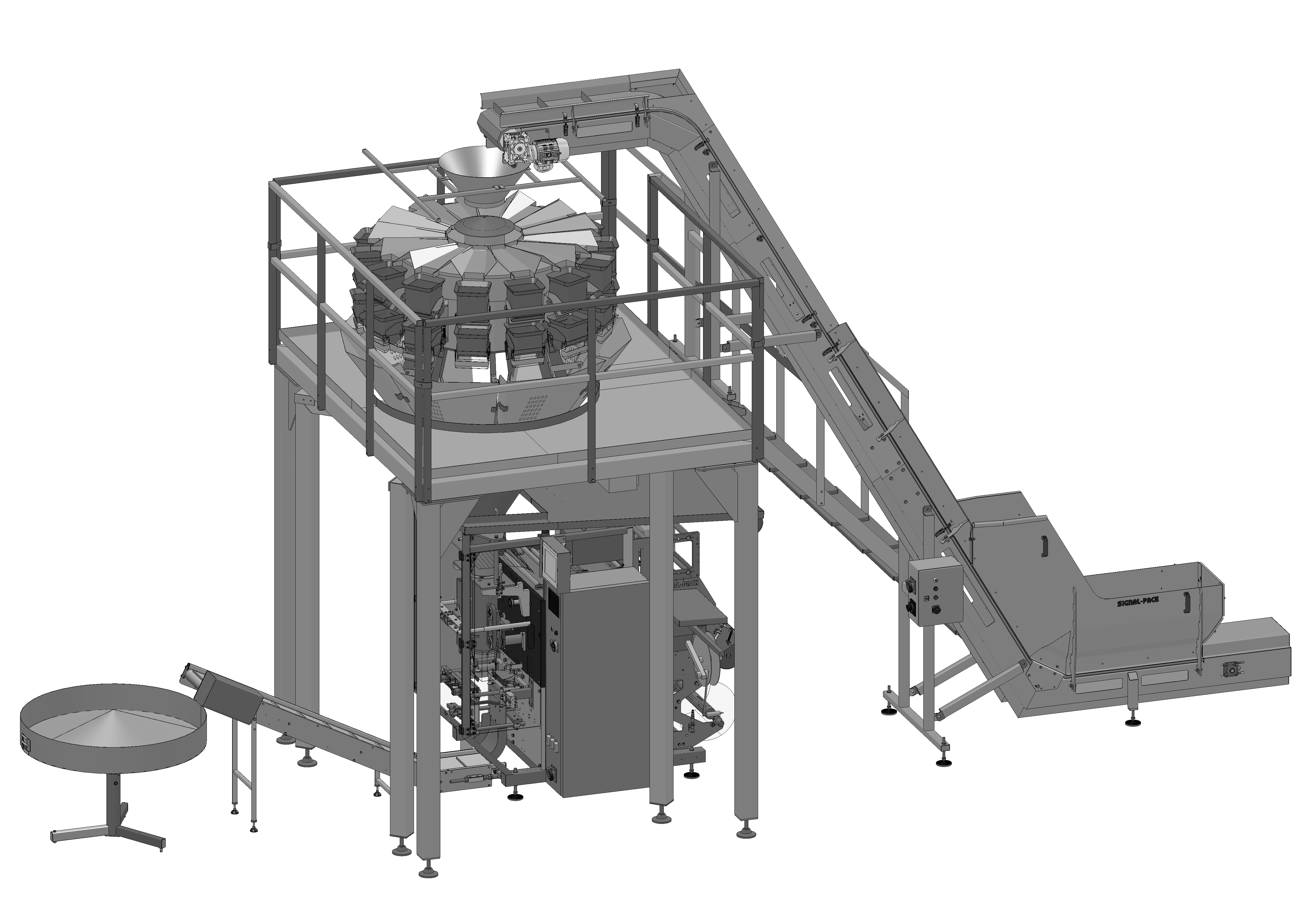

Multihead weigher SP16-1s model (for delicate product dosing) is mounted on a prefabricated frame.

-

Timing hopper TH-2.

-

Z-type feeding conveyor ТZ-1РР.

-

Floor hopper BN-1 model.

-

Tray denester UBT-40 model, 250 g.

-

Horizontal step conveyor with guides, TSH-1 model.

-

Automatic lid closing device U3 model.

-

Horizontal conveyor with two label-applicators.

-

Outfeed roller conveyor.

-

Packaging station table (stainless steel).

-

Roller conveyor for trays with the guides made of stainless steel AISI 304.

-

An operator platform.

-

An inspection roller table.

Our YouTube channel

Our YouTube channel