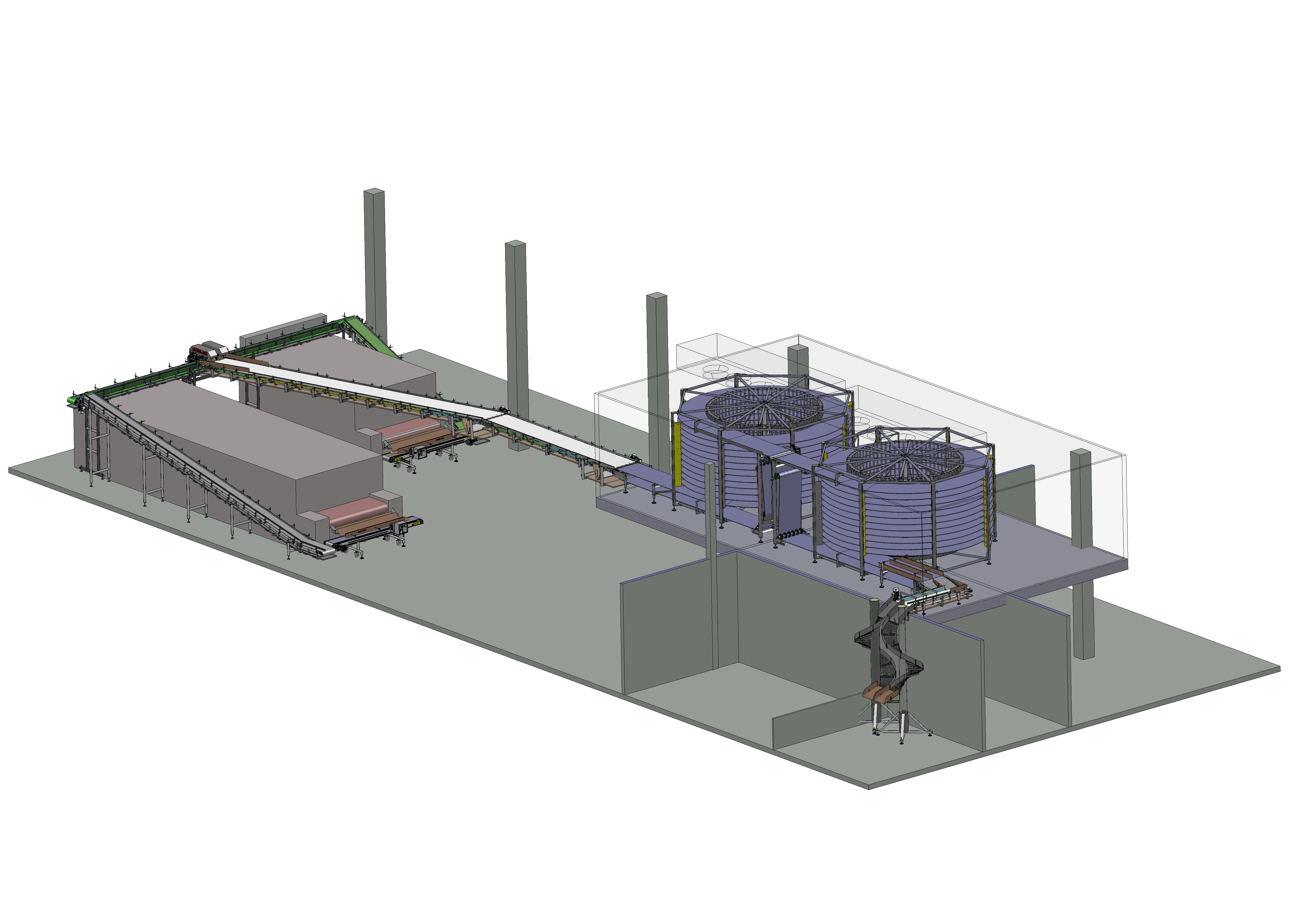

Cooling and packaging of the long loaves

Complete set of the equipment:

-

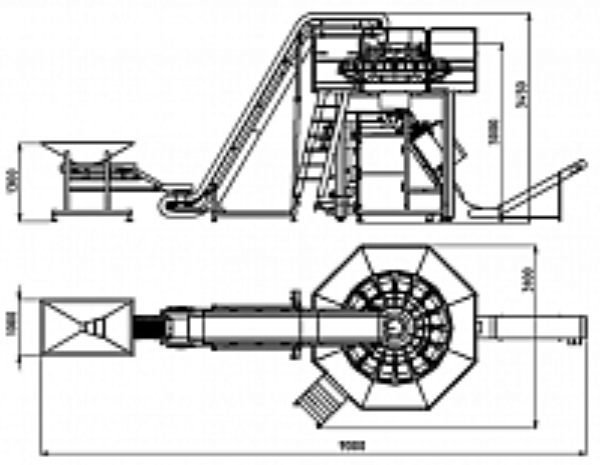

Spiral conveyor

-

Receiving unit for the product coming out of the oven.

-

System of processing conveyors.

-

Horizontal conveyors (3 pcs.)

-

Feed conveyor.

-

Gravity chute.

-

Cooling system.

-

Compressor-receiver unit equipped with the control board.

-

Industrial air-cooler, double flow

-

Evaporative condenser

-

Air cooler control cabinet

-

Automatic equipment of the cooling system

-

Cooling chamber

-

the equipment is made of materials approved to use in the food industry:

-

supporting frame of the conveyor is stainless steel with powder coating RAL (subject to agreement)

-

modular plastic belt NGB S100R, spiral type, POM material, temperature requirements -43…+95 C, without side guards and flights;

-

the cooling chamber is equipped with the mezzanine floor and stairs for cleaning and decontamination of the cooling system and air coolers. The design of mezzanine floor and stairs is structural steel with polymeric coating, RAL (subject to agreement).

-

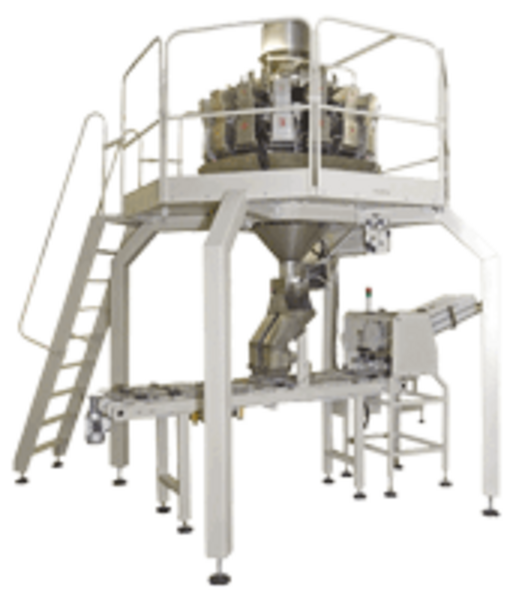

operating conditions of the packaging machine in terms of resistance to climatic factors of the environment comply with GOST 15150-69 for moderately cold climate (UHL 4.2.)

-

antibacterial protection: decontamination facilities for air protection and surfaces in contact with product.

When coming out of the oven the long loaves get into a receiver and are positioned in one row along the conveyor belt. Then the product is fed to the feed conveyor by the processing belts where it is automatically spread out in two rows across the belts and then loaded on a spiral conveyor (cooler). Bread cooling time in a spiral system may vary from 60 to 90 minutes. In the spiral conveyor, long loaves do not change their position relative to the conveyor mesh.

Modular plastic belt with stainless steel lateral rods is applied in spiral systems which enables long life time and complies with safety standards.

After cooling the product is conveyed by the outfeed conveyor and gravity chutes to the packaging station.

The number of control panels and their location are subject to agreement with the Customer.

Our YouTube channel

Our YouTube channel