- For the confectionery industry

- For the bakery industry

- For the dairy industry

- For the pasta industry

- For processing and packaging of vegetables and fruit

- For packaging of semi-finished meat products

- For making and packaging of dumplings, ravioli and vareniks

- For packaging of grocery products

- For tea, coffee packaging

- For snack and nuts packaging

- For seafood packaging

Dumpling making technologies

PRODUCTION OF DUMPLINGS (dough products with filling)

Extrusion and rolling, closed molding formation and cutting are the main technologies applied for processing of dumplings and other similar products made from dough with filling. What are the differences? And which technology is right for you?

The main stage of production is the direct forming of a dumpling. We are going to consider each technology separately and underline their advantages and special features.

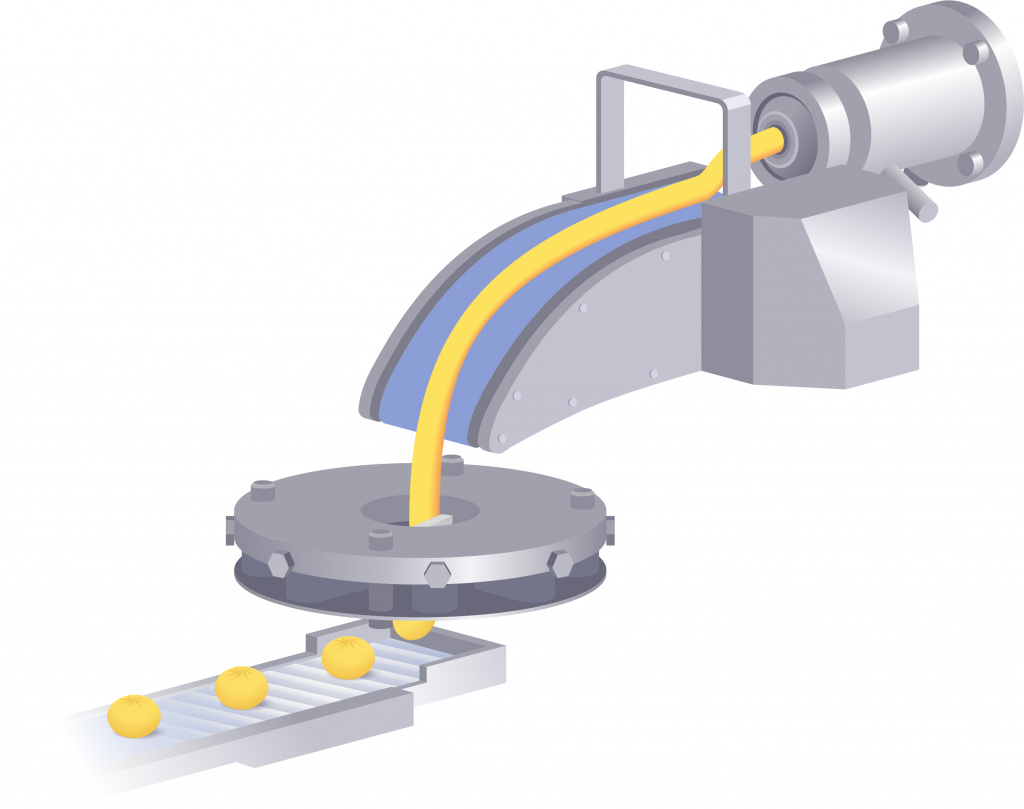

EXTRUSION

Under high pressure the dough is pressed through (for example, with the help of a screw) the ring-shaped channel forming the tube which is then filled. At the next stage, the forming of a product is performed by compressing the tube with filling by molding drums of different configuration.

Disadvantages of the technology:

- excessive dough compacting as the result of screw pressure;

- heating of the dough as it passes through the annular gap: when heated up to 40 ͦ C, the protein coagulates. The structure of the protein changes, making the dough stiff and dense.

As a result, we have a product with relatively large amount of dough (the dough thickness is over 1 mm), with more stiff texture and pasta taste.

The extrusion technology is applied in the automatic multipurpose forming and filling machines by VKP SIGNAL-PACK: EXTRO and EXTRO DUO with the help of which it is possible to produce a wide range of products from dough with different filling.

These automatic machines enables to adjust the dough/filling ratio easily in a range of 30/70-70/30%.

In addition to that, these machines allow to form products made from gluten free dough. To prevent the dough from heating during the extrusion process, a forced cooling system of dough before extrusion is applied in SIGNAL-PACK machines.

The high-power cooling unit pumps a special solution through the cooling jacket at a solution temperature of +5 to -15 ͦС.

ROLLING

The main advantage of the dough rolling technology is the reproduction of homemade dumpling production in industrial scale.

The basic idea of this dumpling machine design is that dough rolling process and final product forming are done within one compact machine unit.

.png)

There are two variants of dough rolling: classical method and V.V. Petukhov method:

CLASSICAL METHOD

The mechanism consists of one or more pairs of rollers, which consistently reduce the thickness of the dough strip. The last pair of rollers might be equipped with a gap adjustment to get the desired dough thickness.

Strengths:

-

proven over decades, classical technology;

-

the texture of the dough is not broken;

-

the finished products are less deformed after molding;

-

opportunity to feed dough by big pieces.

Weaknesse:

- metal-consuming and energy-intensive technology. As it demands two streams of dough strips to mold dumplings.

The advantages of classical technology become clear when operating the machine at high speeds. We apply this method in high production automatic machines AP720, AP740, AP1020 and AP1040.

V. V. PETUKHOV METHOD

The system is represented by four rollers. Two upper rollers rotate towards each other and are designed to take the dough and feed it to the separation rollers. The latter rotate in the opposite direction and divide the dough into two strips. The dough strip thickness depends on the gap between the upper and lower roller pairs.

Advantages:

-

having one drive and four rollers we get two dough strips at the same time;

-

small foot-print and simple design.

Disadvantages:

-

the main disadvantage is mixing and heating of the dough in the area where the dough is divided into two strips;

-

the small distance between the upper rollers, that is why it is better to apply pre- rolled dough strip. If we want to use the dough fed by pieces, then it is necessary to include pre-rolling system of the dough in the complete set which increases the overall dimensions and the cost of equipment;

-

due to the dough mixing in the place of dough division into two strips the dough structure is deformed, which causes the final product deformation when operating at high speeds;

-

high loads on operating actuators of the machine.

In the following, we will consider two methods of forming dumplings.

CLOSED MOLDING FORMATION

It is a method of product molding by cells of the set configuration located in rows on a surface of molding drums.

Two dough strips pass between the molding drums, while the forcemeat is fed continuously between them.

The molding drums are tightly closed during the operation, so when the products are formed the surplus dough "flow" into the molding cells and go into the product itself. The "cutouts" of the dough, which are supposed to be removed, are not formed, that is why quite soft and wet dough can be applied.

Advantages:

-

opportunity to apply the dough of any type, in a wide range of humidity and recipe;

-

opportunity to get a thin dough wrap;

-

opportunity to use any type of fillings – from meat (containing natural beef fat, which exudes flavouring substances during cooking and creates a major flavour kick) to vegetables and fruit;

-

opportunity to get any desired dough-filling ratio in a range of 70/30%;

-

minimal reusable dough cut-offs;

-

this method ensures exceptionally tight "sealing" of the filling, and during cooking the product does not fall apart at the seam, the broth formed by the filling is kept inside.

Disadvantages:

- when products are formed (between the molding drums), dough surplus is distributed among the adjacent products. The products are slightly deformed, and repeat the shape of the drum cells not for one hundred percent.

CUTTING

-

two pre-rolled dough sheets go through two pairs of special rollers for sealing and cutting;

-

the forcemeat is fed with the help of plunger type pumps in portions between the sheets to the exact places;

-

dough residue in the form of a net (cutouts) are returned to the dough.

Advantages:

- cutting allows you to get the ideal product in accordance with a given shape.

Disadvantages:

-

application of low moisture dough (to prevent the dough from sticking);

-

necessity of using hard wheat flour to prepare dough;

-

impossibility of getting thin dough;

-

impossibility of obtaining the product with a filling/dough ratio better than 40/60;

-

complex design of molding and cutting rollers and, consequently, expensive replacement kits;

-

large dimension equipment and high power consumption;

-

complex and troublesome system of filling feed.

This technology is applied mostly in Italian automatic machines for ravioli production. At the end of the last century, these machines filled the Russian market due to the lack of good Russian analogues.

-

Dumpling machines of AP series is a fundamentally new generation of equipment based on rolling technology, today firmly holding leadership in the market.

-

Enormous and constantly growing popularity of dumplings automatic machines of AP series by SIGNAL-PACK among manufacturers of Russia and the countries of near and far abroad is excellent confirmation of that.

This article did not cover the issues related to this topic, such as freezing, packaging, transportation of dumplings, etc. Specialists of VKP SIGNAL-PACK are always eager to answer all questions and offer customized technical solutions.

Contacts: (343) 304 60 40, 304 60 90, 8 800 555 65 76, e-mail: opr@signal-pack.com