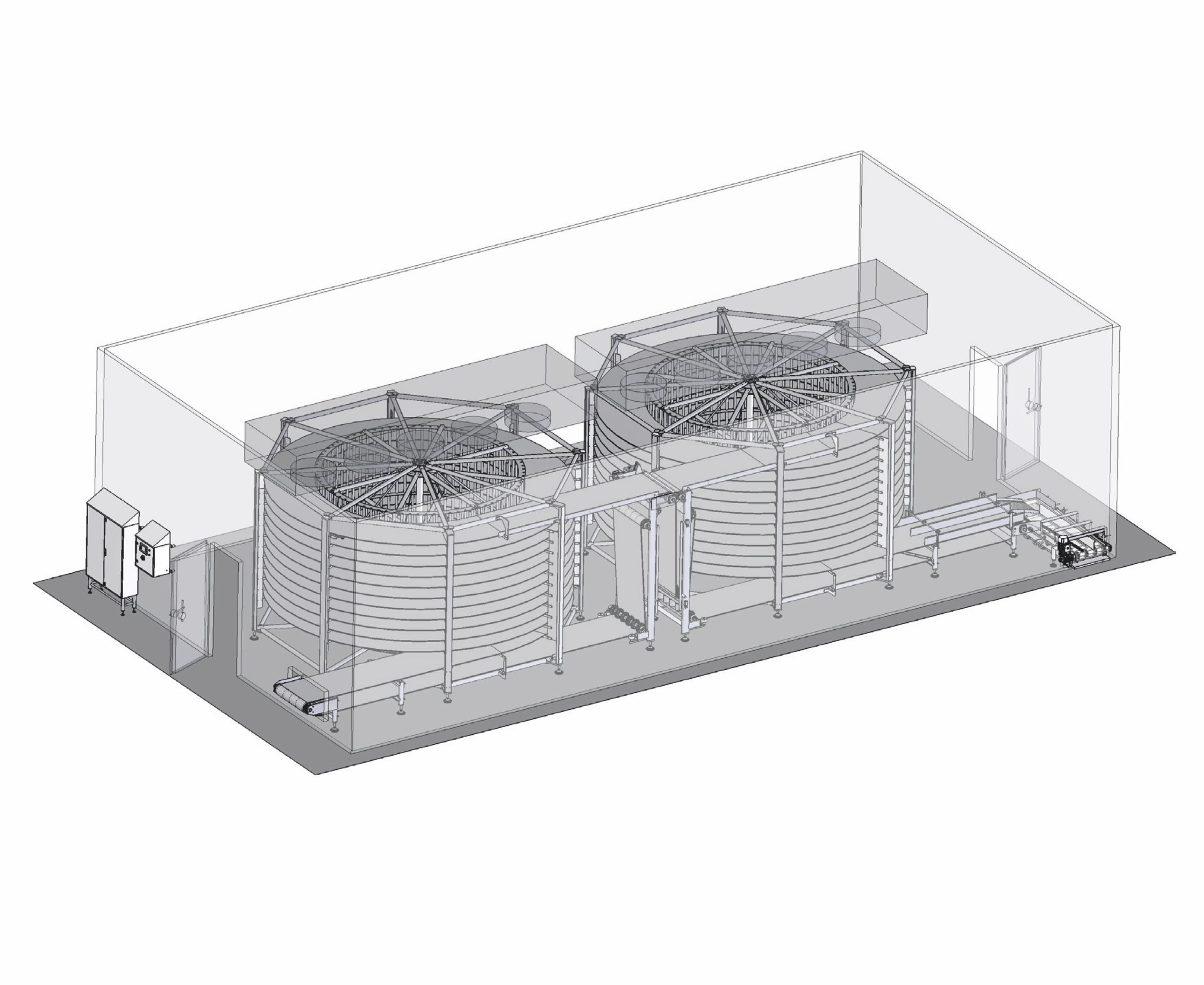

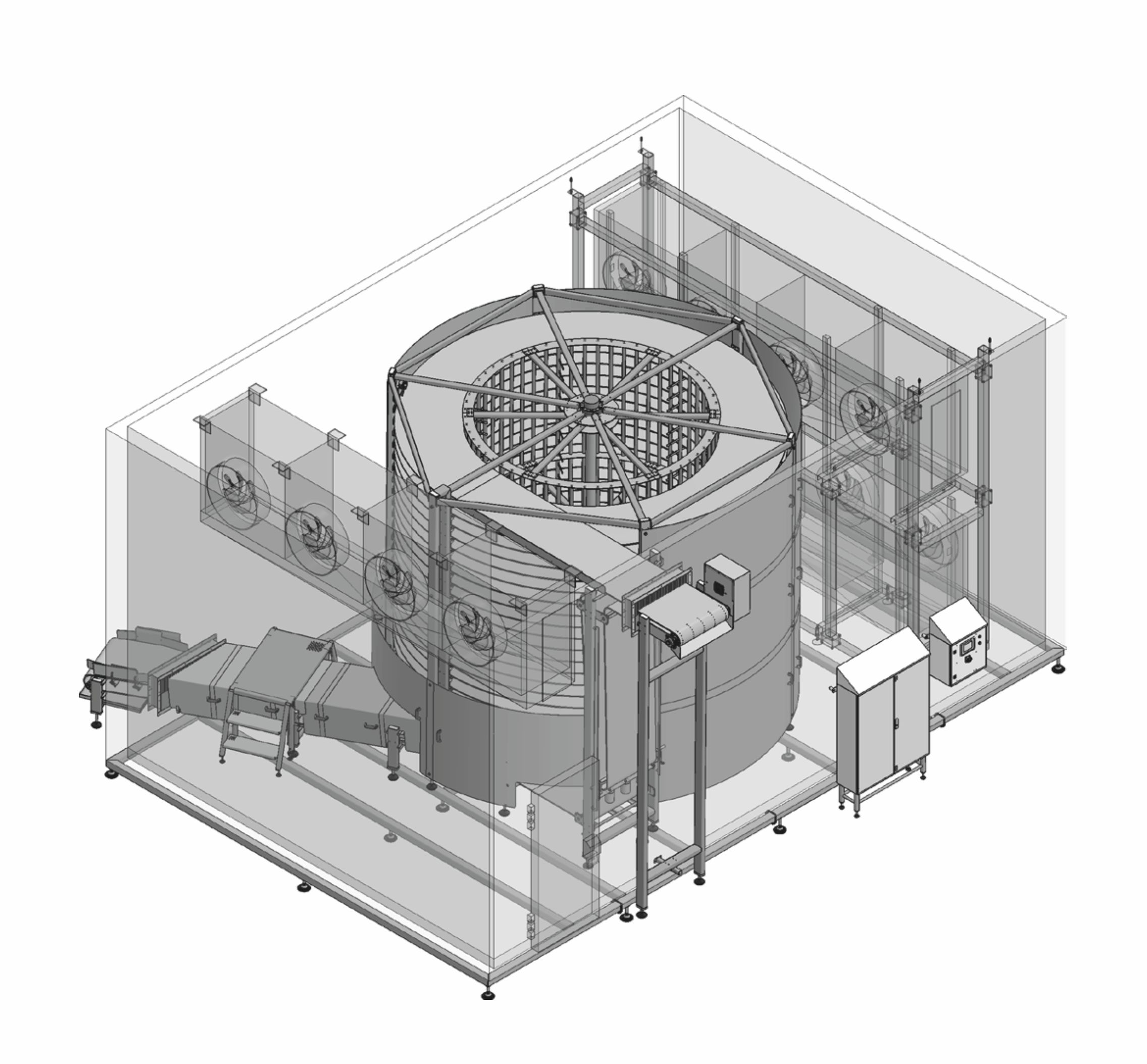

Shock freezing spiral system

FOOD PRODUCT FREEZING LINE APPLICATION enables producing products with an extended shelf life, which ensures transportation over longer distances and, therefore, expands the geography of sales.

The vertical screw conveyor freezing system provides continuous and uniform freezing of different products retaining their taste.

Working temperature range of freezing lines VKP SIGNAL-PACK is set individually, according to the customer technical requirements.

COMPLETE LINE INCLUDES:

-

a spiral conveyor;

-

evaporators

-

a chamber (cooling/freezing)

-

a control cabinet with a panel

OPTIONS:

-

Protective screens

-

Belt washing and drying system

-

Freeze protection of doors

-

Frost protection of drain lines

- Freeze protection of the the cooling system

ADVANTAGES OF THE SPIRAL CONVEYOR SIGNAL-PACK:

-

MULTI-PURPOSE CONVEYER is used for a wide range of semi-finished products: dumplings, vareniki, cutlets, meatballs, Luleh Kebabs, pizza, chicken leg quarters, cakes, fish and meat products, stuffed peppers, stuffed cabbages, etc.

-

UNIFORMITY OF FREEZING. The product, moving on a spiral conveyor, constantly rotates and is blown by a cold stream of air from the air-cooling system from all directions.

- QUALITY AND QUICK FREEZE - products retain their nutritional, organoleptic properties, appearance and original shape

-

EXTENDED SERVICE LIFE (UP TO 10 YEARS). Plastic modular belt application enables working within a temperature range from -73 + 110 0 С

- COMPACT CONSTRUCTION

- PERSONNEL OPTIMIZATION

- Including the reduction of a number of manual operations.

-

INCREASE IN PRODUCTIVITY. Including the organization of a continuous technological process.

BENEFITS OF THE NEW CONTROL PANEL:

-

A clear representation of all key parameters of the system. Convenient control of technological process.

-

Recipes. Quick change of the system parameters for product changeover

- Innovation smart defrost system. Time and money saving.

-

Flexible system of heat exchange rate setting enables perfect tuning of system to any product.

-

Ease of control enables performing an operator functions even by those who has not gained any special training

-

Detailed statistics on operation, alarms, and load of the freezing system. Visual analysis of operational efficiency.

- The minimum power consumption is achieved by well-designed placing of the vaporizer.

- No product cracking thanks to a product flow arrangement system and heat exchange rate control.

Our YouTube channel

Our YouTube channel